Quality Control in Planar Imaging

- Quality Assurance(QA)

- Accreditation agencies- JCAHO (The Joint Commission), ACR, ICANL, and JRCNMT (just to name a few)

- Federal regulation agencies - NRC, FDA, and DOT

- QA at the procedural level (Exam) - requires evaluation at each step in the overall process

- Scheduling

- Patient History/Interview

- Radiopharmaceutical and administration

- Acquiring the study

- Physician interpretation

- Patient Satisfaction (TQM)

- QA at the department level

- Compliance with regulations

- Radiopharmaceutical administration

- Procedures

- Interpretation of the exam

- Record keeping

- Continuing eduction

- Quality Control - is but a part of an overall QA program

- General comments

- Routine QC testing is an essential component to any nuclear medicine department

- Action/trigger levels must be set for corrective measures

- Establish a benchmark - follow it - What does the the literature say - what does the manufacturer recommend?

- The overall goal is quality!

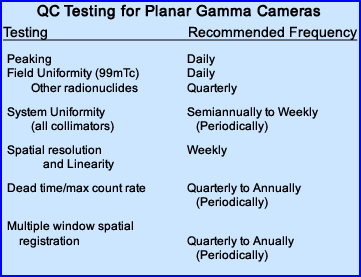

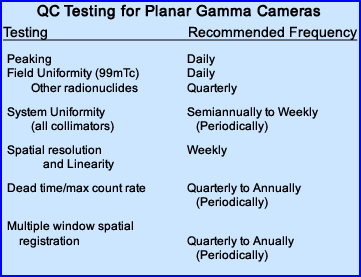

- Peaking

- Intrinsic or extrinsic (scatter free source)

- Source should cover the entire FOV, but that may not be practical (consider your distance)

- Never peak off a patient (too much scatter)

- The camera should be peaked every morning on the energy peaks of all radionuclides being used that day

- More modern systems have auto-peaking where the peak is split in two and adjusted until the counts on either side are equal

- Energy resolution should be compared with manufacturer's guideline (most systems do not have this capacity)

- HV does fluctuate so expect the peak to move a few keV in either direction

- Multi-head cameras require greater adjustments, because the heads must be "in tune" with each other. In addition there is less tolerance when two or more heads being where acquire is data. What do you think might happen if there were slight changes in keV from one head to the other?

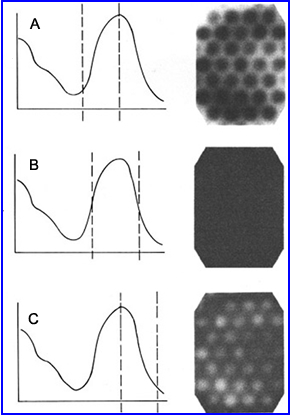

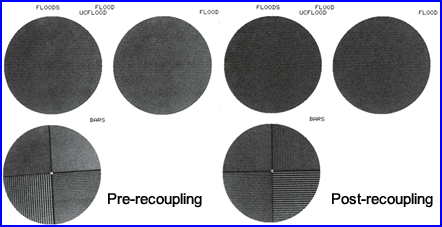

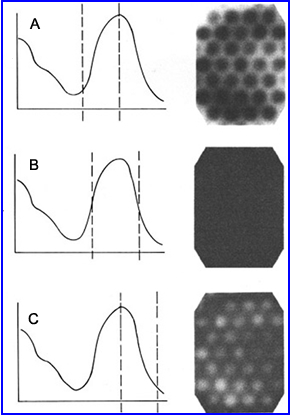

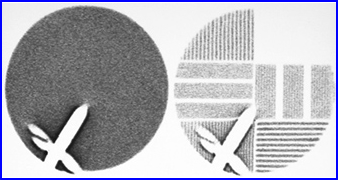

- Photopeak adjustment and the effects on the image

- A - decreases the amount of scatter, however, too much to the right will cause the PMTs to show up hot

- B - is a normal window with LLD and ULD are set appropriately

- C - asymmetrical shift to the left causes the PMTs to appear cold surround by a hot background

- Off peaking may help resolve camera issues:

- Determine if detector needs an HV adjustment

- May show loss of optical coupling

- Identify crystal deterioration

- What might occur if a bone scan was acquired with peak A

- What might occur if a liver scan was acquired in peak C

- Modern gamma cameras are able to correct for asymmetric windows

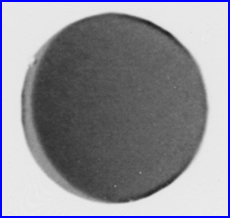

- Uniformity Flood

- Is the #1 QC procedure to evaluate the camera's ability to operate correctly. This procedure can be done in/extrinsic

- Intrinsic flood

- With the collimator off acquire a <1.0 mC 99mTc source, in a syringe. Some cameras systems may require as little as 250 μCi (or even less)

- The source should be placed in the center of the detector at a distance of at least 5 FOVs. This will causes <1% variation of photon flux within the entire areas of the crystal's surface

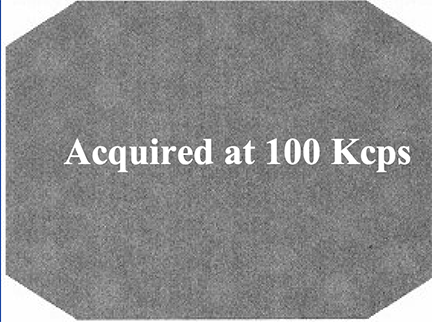

- To prevent deadtime from occurring the rate should not exceed 20k cps

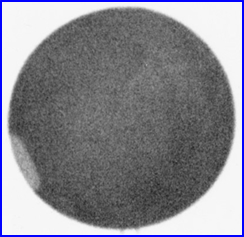

- Some systems require a lead mask placed around the edge of the crystal which prevents gamma rays from interacting with the edge packing. What does edge packing look like? It will be a hot rim seen at the edges of the FOV, where the rest of the crystal will show significantly less uptake (see below)

- Some dual-headed systems require an additional test where a low activity point source is placed between the heads (may require 100 to 250 μCi). This creates a large non-uniform spot which is required prior to taking the intrinsic flood source

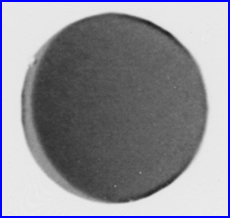

- Finally, make sure that there is no other radioactive source interfering with the intrinsic flood. The above is and example of this problem

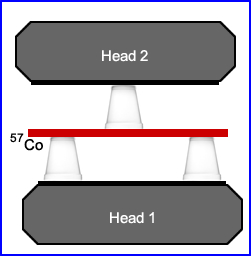

- Extrinsic Flood

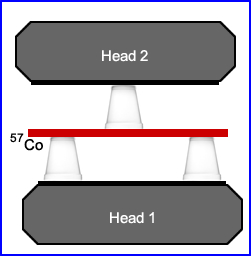

- Using either a 57Co sheet or a refillable flood with 5 - 15 mCi of 99mTc place it on the collimator's surface.

- If there are 2 heads then place 4 Styrofoam cups on the bottom and 1 at the top. This will assure equal distance between both heads

- Intrinsic/extrinsic uniformity

- First check your photopeak before you do anything else

- Literature suggests that you collect between 2 - 6 million counts. Would there be an advantage of collecting 10 to 15 million counts?

- When doing this QC procedure acquire with the uniformity correction off and another one with it on

- Concerns

- Intrinsic is more of a hassle because the collimator must be removed, however, it is very effective in determining uniformity and in acquiring a uniformity correction matrix

- Extrinsic - 57Co requires that you buy a new one every couple of years (what's the half-life of 57Co?). It can also contain 58/59Co impurities that become less noticeable over time

- Extrinsic - refillable plastic floods is yet another method of collecting an extrinsic flood. However, can be messy since it needs to be mixed with an air bubble and then "burped." One other concern I've experienced is that large field of view refillable plastic food may bulge in the center

- The human eye can detect ~5% variation, which means that quantitative measures that should be employed since variations may occur below 5%

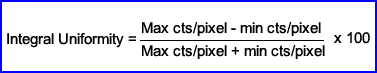

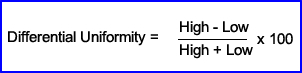

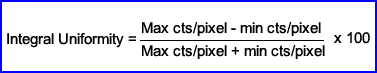

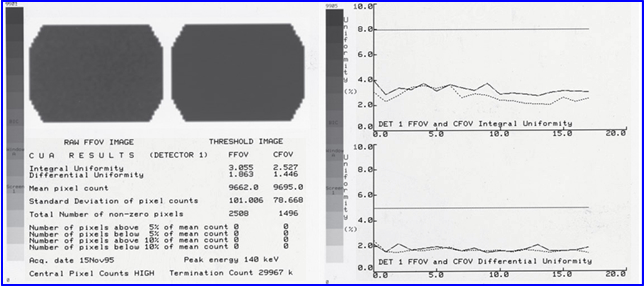

- Two quantification formulas (you must know)

- Integral uniformity assess the entire flood at the pixel level and finds the pixel with the least counts and the one with the most counts are applied. Those numbers are used in the above formula. This gives you an overall picture on how uniform the flood is. Over time, if the % slowly increases then service dude needs to called in for a PM

- Differential uniformity looks a 5 pixel segment, either vertically or horizontally and determines what the counts are in each pixel. The one with the most and less counts are placed into the formula. This value shows non uniformity over a small segment of the camera

- Integral uniformity will always be greater or equal, but never less than differential uniformity (why?)

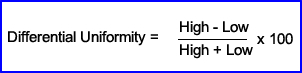

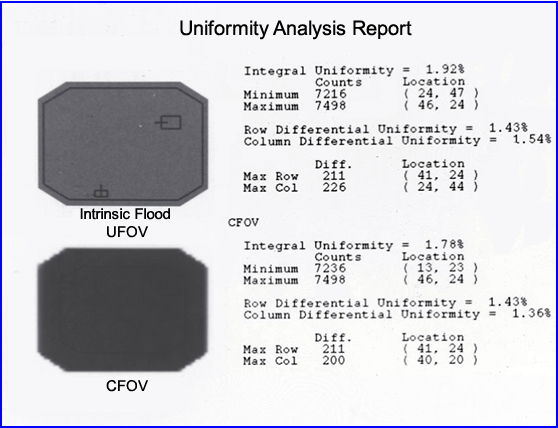

- Example I

- Both integral and differential calculations are displayed with FFOV (Full Field of View) and CFOV (Center Field of View)

- To the left is a Levy-Jenning plot where the solid line is the FFOV and the dotted is CFOV for integral and differential uniformity over time

- Evaluation of these calculations and graphs, over time that help determine when the system needs to be re-tuned and/or serviced

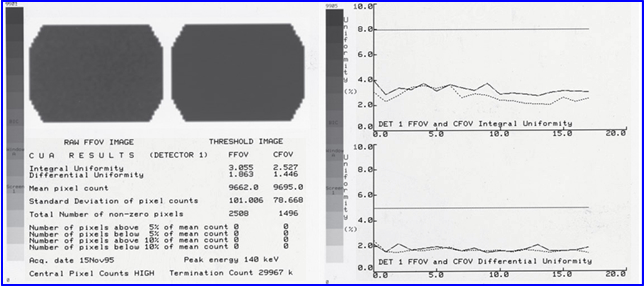

- Example II - Goal of this system is to find the area of the greatest non-uniformity

- Boxes indicate the area of greatest non uniformity in the UFOV (Useful Field of View) and CFOV. This generates new integral and differential uniformities. Why is there a difference?

- Boxes can be moved around at the discretion of the user

- The greatest non-uniformity within each box displays a differential uniformity via the vertical and horizontal line that determines at the UFOV and CFOV (note the locations between both boxes)

- Additional comments

- What are the differences between FFOV, UFOV, and CFOV?

- FFOV (Full Field of View) cover the entire detector's surface, however, counts tend to fluctuate at the extreme edges of the FOV which is caused by edge packing. This may falsely elevate the integral value

- UFOV (Useful Field of View) is 95% of the FOV's area. Notice the outline drawn slightly inside the edge of the crystal (example II). This removes the edge packing effect, however, it may miss a PMT problem at the edge of the crystal

- CFOV (Center Field of View) is 75% of the UFOV

- Relationship of integral differential values: FFOV ≥ UFOV ≥ CFOV

- Integral uniformity should be between 1 - 5%. According to NEMA integral uniformity should be ≤ 5% @ 5 million counts

- For SPECT intrinsic uniformity should be ≤ 3% and extrinsic floods tend to range a little higher, between 4 - 6%. This may be do to the impurities of the flood source and/or collimator

- Set the action level at 5% (or less). If you hit the action level you should first try to require a new correction map. If that fails then call the service dude

- Count profiles can also be drawn by the technologist to further evaluation of pixel variation

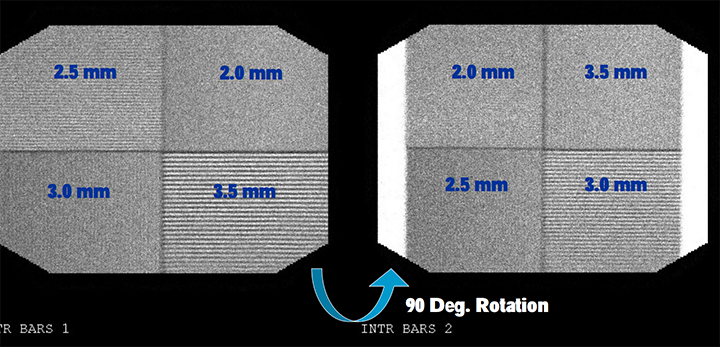

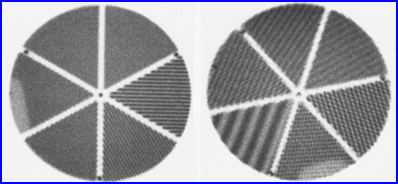

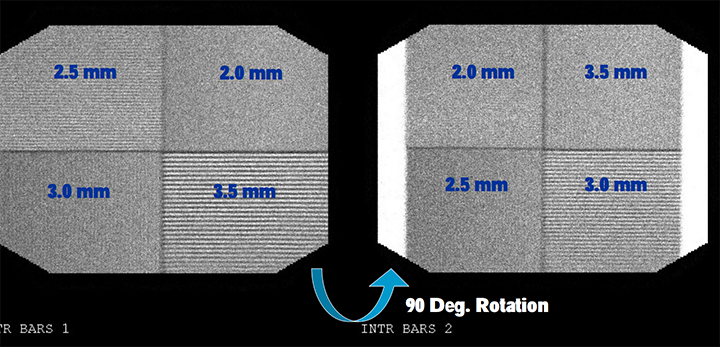

- Other measurements for the Bar Phantoms

- Bar size assessment is only semi-quantitative, since it does not pinpoint the exact resolution of the imaging system. It only shows resolution to the smallest bars

- Linearity can also be evaluated by eyeballing the imaging system's ability to duplicate a straight line. Refer to the last lecture for an example

- A 0.4mm deviation in linearity will produce 8% non uniformity

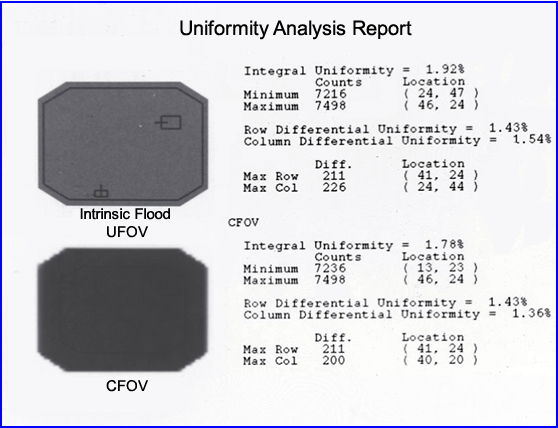

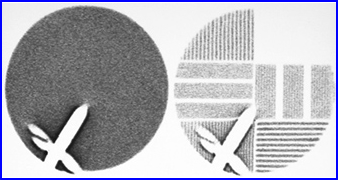

- Moire pattern

- This occurs when the holes within collimator closely match the size bar being imaged. This causes an interference pattern referred to as a Morie pattern

- This pattern is more typically seen in HS, ME, and HE collimators

- Example - consider a HE collimator having a larger diameter and more lead between the septas. Thickness and diameter (closely) match the size of the smaller bars creating the Morie pattern

- We see this pattern around us

- Two sets of circles create this pattern as you move them around

- In digital photography if the resolution of the camera is similar to the object(s) being imaged, what do you get?

- Incredible Moire Pattern - YouTube

- Spatial resolution should be evaluated at surface of the detector and at 10 cm distance

- Using a bar phantom place it 10 cm away from source. Then place scatter media between the source and detector (Lucite or water)

- Acquire 5 million counts

- Matrix should be set at 512 x 512 Why not 256?

- Acquire it extrinsically

- Quantify your results - The less accurate method is done as follows

- Identify the smallest bars the system that resolved and multiple that value by 1.75

- As an example if you can resolve 2.5 mm bars, but not 2.0 mm

- Apply the value - 2.5 x 1.75 = 4.4 mm

- Now calculate the next set of bars that you cannot resolve and apply the same formula - 2.0mm x 1.75 = 3.4 mm

- This tells you that your FWHM is between 4.4 and 3.4 mm

- The more accurate method - The Line Sored Function (LSF) approach

- Select the tube size that is 1/2 the size of the smallest bars that your imaging system can resolved or <1/4 the size of of the system's apparent FWHM

- Fill the plastic tube with several μCi of 99mTc

- Acquire an image in a 512 x 512 matrix

- Apply a count profile across the LSF and make sure that you have at least 5 data points on either of the FWHM

- Find the 1/2 point and count your pixels. Then convert your pixels the cm. We did this part in our last lecture

- Atypical QC procedures

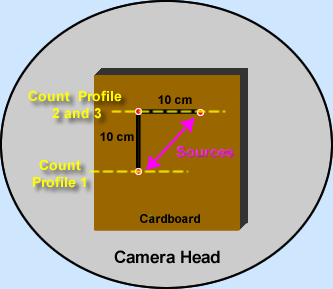

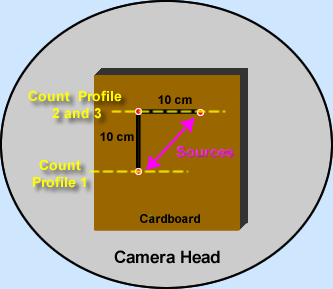

- Pixel size calculation

- Knowing the FOV and applying a specific matrix size allows you to quantify the actual size of the pixel

- Example - If the FOV of a camera is 50 cm across and the matrix is 128 x 128, what is the size of a pixel?

- 50 cm/128 = 3.9 mm/pixel. Now prove it!

- To verify this value the following procedure is recommended

- Take large enough piece of cardboard draw two 10 cm lines at right angles to each

- Place the drops of 99mTc at each end of both lines and a third one where the lines intersect forming the right angle (red circles)

- Place cardboard on surface of FOV so that it lines up with the camera's x and y axis

- Apply a count profiles at each end point of the two lines and at the point where they intersect (count profiles are yellow dashes)

- Count the amount of pixels between the peak of the two points for x and y. These measures defines the amount of pixels in 10 cm

- From a clinical standpoint why is it important to know the size of a pixel?

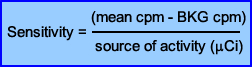

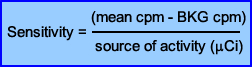

- Sensitivity check

- Determine the amount of counts a gamma camera can acquire based on how much activity is present

- Sensitivity test is as follows

- Measure 1 - 2 mCi of 99mTc and place the solution into a petri dish

- Measure the amount of activity remaining in the syringe in order to determine the exact amount of activity in the dish

- Dilute the solution in the dish so that the solution is about 3 mm deep

- Place the dish on top of the collimator and make sure that the count rate is <10k cps

- Count for 1 minute and repeat 9 more times and record your data. Don't forget to take a 1 minute BKG count

- Now find the mean value of the cpm and apply it to the above formula

- Homework: click it and calculate your camera's sensitivity

- This test assesses the collimator more than the camera and the counts should be stable over time

- If you have more than one camera head, then the sensitivity for the corresponding head should vary <5%

- While this procedure is not required, you book recommends this be done quarterly or semiannually

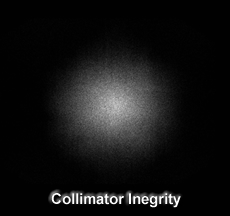

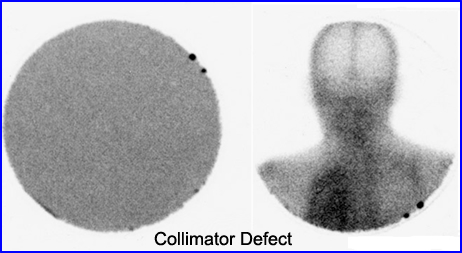

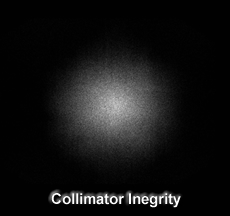

- Collimator integrity

- Determine if any of the septa have been "mashed" you can look underneath the collimator or

- Take a 20mCi point source of 99mTc and place it 20 feet away from the camera and extrinsically acquire 1 - 2.5 million count image

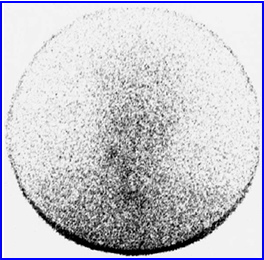

- If there is not damage to the septa a large round ball of activity will be seen

- Damage is noted when the "ball" of activity lacks symmetry

- It is recommended that one evaluates all collimators on a quarterly bases

- Visual assessment of the septa is suggested and when damage needs to be ruled out preform the above procedure

- In order to assure image uniformity, collimator uniformity must approach intrinsic uniformity

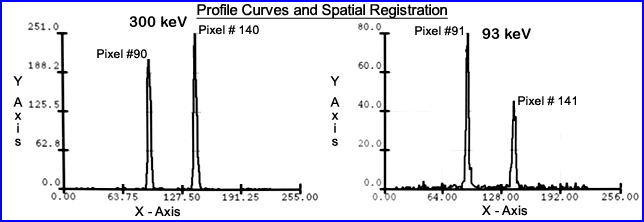

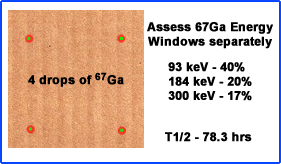

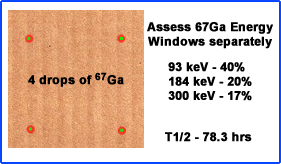

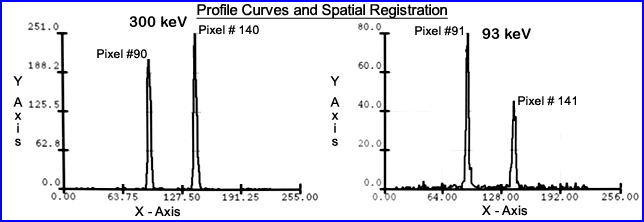

- Multiple window spatial registration

- Determines if multi-energy radionuclides are being recorded in their correct energy peaks at the right location. Sometimes an imaging system will mis-register the different photo-peak's

- Approach 1

(extrinsic)

- Place 1 to 2 drops activity in 4 locations on a piece of cardboard

- Acquire each energy peak separately for the same amount of time

- Subtract the same energy peak from the other and if there is any superimposition remaining then the system has a mis-registred (essentially it is off peak)

- Approach 2 (extrinsic)

- From the above exam with the cardboard and dots draw count profiles and evaluate each energy peak. If spatial registration is correct then the pixel with the maximum amount of activity will have the highest counts for each energy peaks

- Given a multiple peak radionuclide (67Ga) the above shows that the highest counts for the 93 keV window is at pixel 91 and 141. Looking at the same locations, 300 keV at 140/141 has greater counts when compared to 93 keV in the same location

- Not the percent energy gammas of gallium: 93 keV - 40%, 184 keV - 24% 397 keV - 22%, and 388 keV - 7%

- If the highest counts are not within all three (same) pixels then there the system is mis-registering

- Approach 3 (Intrinsically)

- With a point source place a bar phantom on the crystal's surface

- Acquire count in each energy peak

- Then subtract one from the other

- If any portion of the bar remains then mis-registration is present

- I'm not sure I agree with this setup

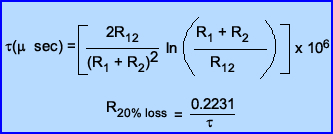

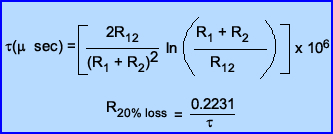

- Count-Rate and deadtime

- Certain studies, such as 1st pass cardiac exams, require high count rates, however, the maximum amount of activity that can be acquired by an imaging system should not exceed more than a 20% loss in counts. Anything beyond 20% results will significantly distort the acquiring data. How do you determine this?

- Two source method for determining 20% loss

- Can be done intrinsic or extrinsic (would you prefer intrinsic or extrinsic?)

- Attain two sources of 99mTc that have similar amounts of activity which generate ~20k counts each (define as R1 and R2)

- The combined sources should produce approximate 20% count loss. Confirm the actual amount of activity from the manufacturer

- Acquire counts for 100 seconds with some type of scatter medium between the source(s) and the detector. (can you suggest a type of scatter medium?) Acquire the follow:

- Count R1

- Count R2

- Count R1 and R2

- Repeat this process in reverse order as a control

- Apply the recorded data to the formula. Twenty percent loss can then be verified with the vendor's benchmark

- Other variables to consider that would effect deadtime are

- Type of collimation

- Crystal thickness

- Percent window adjustment

- Edge masking (physical or electron) when intrinsic application is applied

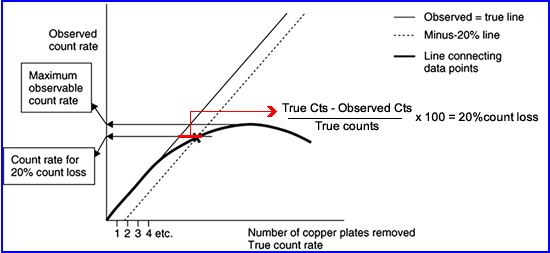

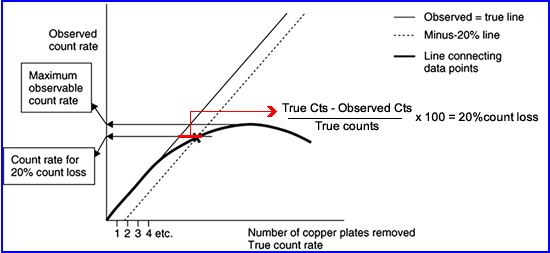

- Copper plate method to determine deadtime loss

- Remove the collimator and acquire a 20 mCi source of 99mTc placed 150 cm away from camera surface

- Take 25 copper plates (1-mm in thickness) and place all of them on the crystal and between the source

- Preset time (~1 minute) and measure/record the counts. Then remove 1 copper plate at a time and repeat/record the acquisition

- Graph results are seen above

- Describe the results seen as copper plates are removed. Can you determine where 20% count loss is seen?

- Acceptance Testing new equipment

- National Electrical Manufacturers Association (NEMA)

- All camera cameras and associated software are tested by NEMA. This organization defines an instrument's level of performance

- QC procedures are found in NU-1-2001 and are not routinely done by a technologist on specific manufactured gamma cameras

- For more NEMA testing on nuclear medicine imaging equipment look here and bring your credit card

- Once specific standards have been established by NEMA the manufacturer of the camera will randomly test the equipment leaving the factory to assure that these standards are continually being met

- Acceptance testing and benchmarking

- Prior to clinical applications of a new camera Joint Commission requires that an imaging system should undergo acceptance testing

- What the department should? Hire an outside physicist to perform NEMA tests on the new camera to see if it meets the established standards

- Benchmarking occurs after the camera passes NEMA standards which include all routine QC procedures that a technologist would normally apply. This data is saved for future reference

- If the camera falls below the established benchmark then you should call the service dude and get your camera tuned

- In an ideal world, acceptance testing should be done every 1 - 3 years and benchmarking should follow each major repair and PM

- Trouble shooting your scintillation camera

- Wrong photopeak - always check you peak to make sure you are imaging in the right window

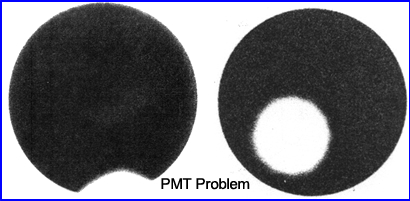

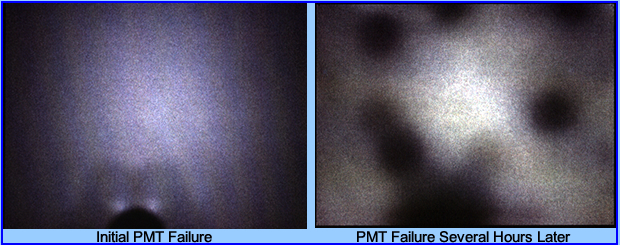

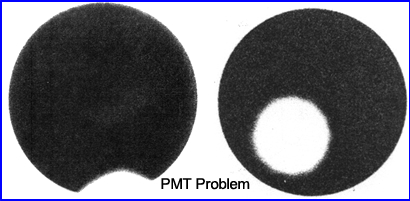

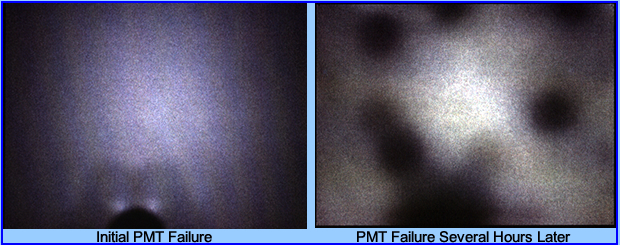

- PMT problem

- PMT failure via alteration of HV, Pre-amp failure, or loss of vacuum in the tube

- Initial PMT failure causes the system to have issues with its position circuitry. Over time a single PMTs failed corrupted the auto-tuning circuitry causing catastrophic failure

http://www.cancercare.mb.ca/home/cancer_research/medical_physics/imaging_physics/what_we_do/

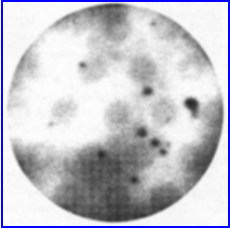

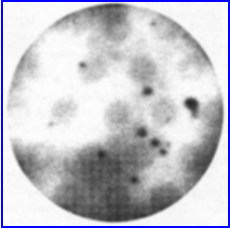

- Cracked crystal occurs when something hard smacks it! Notice how the edges of the crack are hot which is is do to the edge packing effect. Replacement of the crystal is essential and expensive. This must be done before clinical imaging continues

- Rotate the bar phantom every week is suggested. Why might this be a good idea?

- Measles occurs when the seal is broken. The hygroscopic crystal absorbed moisture and the NaI turns yellow causing it to loose some its scintillation properties

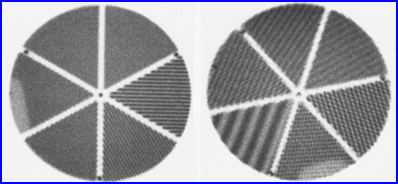

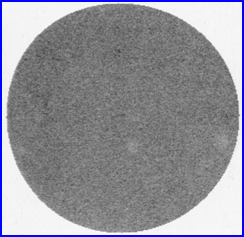

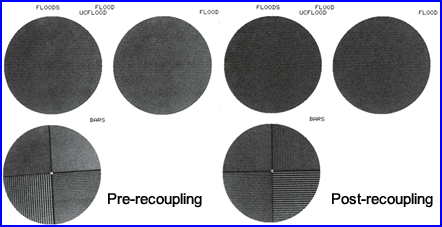

- Loss of automated correction will adversely effect imaging quality. The image on the left was collected prior to retuning while the one on the right was acquired after a new 30 million count correction map was attained. Note the subtler difference

- Off-peaking - this was discussed earlier in the lecture

- Poor coupling between the crystal and the PMTs

- I am told by service dude that the silicon gel used to couple the PMTs to the crystal dries out over time and it should be replace every 10 years.

- This subtle effects can be seen in an camera's flood and bars pre/post coupling

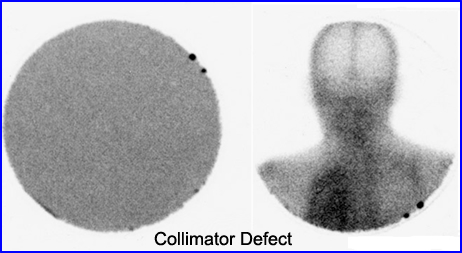

- Collimator defect causes an usual area of interest. What made the two hot spots? Could this effect acquired data if the spots were more centrally located?

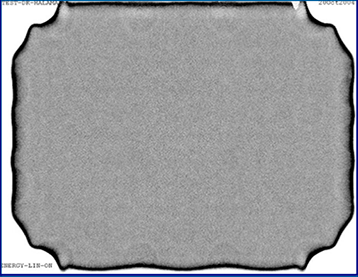

- Refillable flood problem

- Three types of problems can occur with refillable flood: it's not mixed well enough, it has an air bubble, or it can bulge in the center (usually more a problem with cameras that have a large FOV cameras)

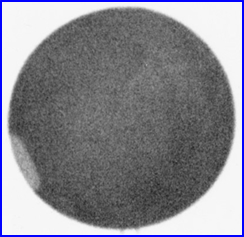

- Above is an example of air in the flood - why does it appear this way?1

- Given the above image what abnormality is being displayed?1

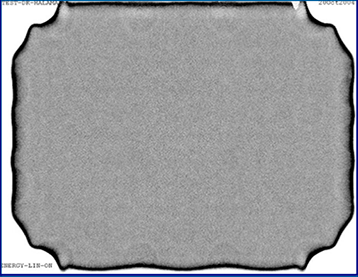

- This morning flood image image was collected at 100k cps. Why is this a bad idea? Is the an acceptable image?1

- Problem with the photographic system

- Dust can lay up top of the lens of a formatting system that used x-ray film

- While we rarely use this type of device, the above is an example of the problem. To fix the problem, vacuum the dust of the optical lens inside the unit

- This is a great review on Gamma Camera QC - https://www.aapm.org/meetings/amos2/pdf/35-9798-70158-156.pdf

Return to the Table of Content

Reference - QCProtocols Gamma Camera & SPECT Systems by JR Halama, et al.1

2/23