- Causes of Nonuniformity

- Define uniformity - ability to reproduce a uniform distribution of radiation being detected. Consider this when assess a flood source that has uniform distribution and what causes it not be uniform

- Response to where the photon interacts with the crystal (above) will cause a lack of response as it approaches the edge of the PMT (photocathode)

- Where there are two PMT edges interact the positioning of the events are directed at each other further causing misposition of photon location

- Z-pulse variation from each PMT is another source of nonuniformity. Results in (Both a. and b.):

- Causes cold and hot PMTs

- Causes wavy lines

- Where there are two PMT edges interact the positioning of the events are directed at each other further causing misposition of photon location

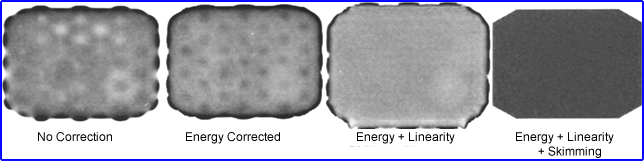

- Uniformity Corrections - nonuniformity can have as much as +/- 15% variation resulting is visual hot/cold spots

- Manually using a point source all PMTs can be tuned and this reduce nonuniform to about +/10%

- Count Skimming/Adding

- Determines the average counts per pixel from a uniform source

- Deviations per pixel are then stored

- As an image is collected counts are either subtracted (skimmed off) or added "on the fly"

- Every isotope used with this camera requires its own correction matrix

- Nonuniformity is reduced to about +/-5%

- Energy and linearity corrections

- Linearity corrections are stored at the pixel level usually at the factory or by service dude

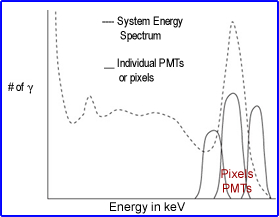

- Energy peaks vary slightly at the PMT and pixel level

- Energy correction of the photopeak is applied at the pixel level with )Z

- When acquiring data these corrections factors are applied at the pixel level

- End results - improves energy resolution and reduces scatter

- Linearity correction

- Application of an appropriate linear phantom data is acquired in one projection to collect X coordinates. The system then creates )X to correct the positions which generates a straight line in the X direction

- Phantom is rotated 90 degrees to determine )Y positions applied

- Corrections are then applied to all pixels in the matrix

- End results

- Energy and linear corrections will generate a 3-5% non uniformity

- Adding count skimming, isotope specific acquisition with appropriate collimator will generate 1-3% nonuniformity

- Up to a 120 million count correction flood (sensitivity map) must be acquired to have a correction map

- Autotuning

- PMTs HV drift over time and autotuning is applied by making small adjustments as needed to assure that the variation of the pulse does not change

- Methods

- Photopeak monitoring - HV is monitored at PMT level and adjusted with a reference value

- Split-Photopeak monitoring - Each PMT has two high peak windows. When drifting occurs HV is adjusted by maintaining a ratio between the two peaks

- LED monitoring - LED flashes and generates photoelectron with the PMTs. The LED sets the standard and the PMTs adjust the HV when there is a drift in photoelectron collection

- If a PMT goes out of tune more than 3 keV then service dude takes over because the PMT can no longer correct itself

- Other points of interest

- PMTs are effected by magnetic fields and may be shields with mu-metal to reduce any low magnetic field. Would PMTs be able to function near an MRI unit?

- Keep your camera's room temperature constant with a suggested range of 68 to 70 degrees F.

- If temperature increases by 9 degrees or more within an hour the crystal may crack

- Beware of power surges and always use a batter backup

- Consider gamma ray photon interference from adjacent rooms and/or PET

- An old camera may show crystal hydration or optical gel deterioration

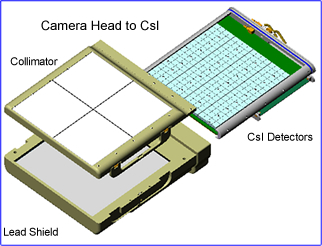

- Pixelated detector

- Has many small crystals, usually made of semiconductor material

- Each crystal is attached to a single position-sensitive photomultiplier (PSPMT)

- Collimator holes are lined up to individual crystals

- It's like creating a matrix on the detector head

- Resolution my not be as good, however, sensitivity is outstanding, and it allows for first pass procedures of the myocardium

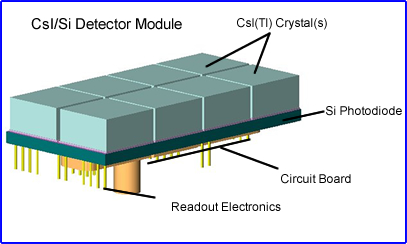

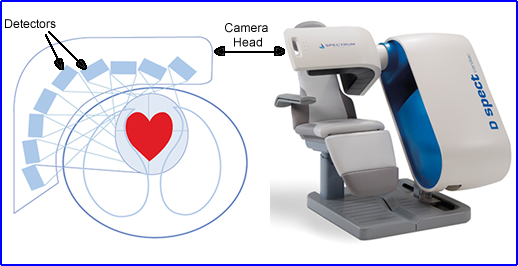

- CZT Camera (Cardiac)

- Pixeled system with CsI(Tl) crystals with silicon photodiodes

- There are 9 detectors in the camera head which rotate back and forth

- Has great counting statistics and shorten's imaging time

- Crystal materials

- NaI(Tl), CsI(Tl), CsI(Na), LaBr3 each have different properties (density, deadtime, light output, etc.)

- CZT is a semiconductor - better energy resolution and less thickness needed. It also has to operate below room temperature